November 2021, Vol. 248, No. 11

Features

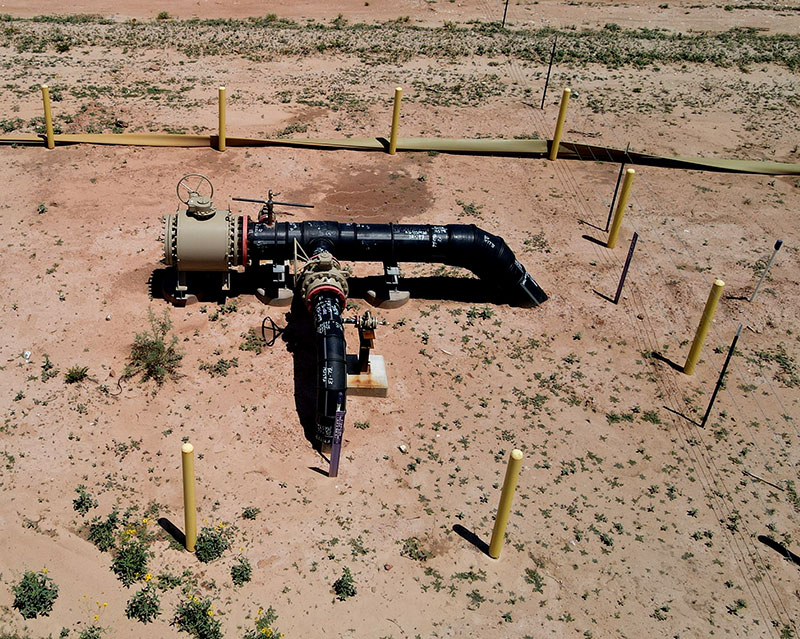

15-Mile Pipeline Provides Path for High-Temp Water from Deep Underground

By Steve Cooper, Infrastructure Reporter

The Delaware Basin, part of the Permian Basin, is currently the most active area in the United States by rig count for oil and gas production. Bringing oil and gas to the surface also brings produced water, either found in the underground formations or from fracking. There can be anywhere from four to ten barrels of brackish water produced for each barrel of oil. To capture those vast amounts of water, Crestwood Equity Partners LP, designed a saltwater disposal facility and pipeline network.

The Desert Hills pipeline would eventually use approximately 80,000 feet of polyethylene, raised temperature (PE-RT) high-density polyethylene (HDPE) PE 4710 pipe to provide E&P companies with a way to dispose of the water.

According to Crestwood, the entire Delaware Basin produced water gathering volumes averaged 48 million barrels during the first quarter 2021. The engineered pipe was selected because of the sustained, elevated temperature of the produced water reaching Crestwood’s system in combination with the 50 to 150 psi operating pressure of the pipelines.

Crestwood owns and operates midstream businesses in multiple shale resource plays across the United States and is engaged in the gathering, processing, treating, compression, storage and transportation of natural gas; storage, transportation, terminaling and marketing of NGLs; gathering, storage, terminaling and marketing of crude oil; and gathering and disposal of produced water.

“We looked at the various options for our water gathering system when we were building the Desert Hills pipeline,” explained Eric Ormond, senior vice president, Engineering & Project Management at Crestwood. “This included chillers, which tend to be costly to operate and use a lot of electricity. We considered stainless steel pipe, but it would be expensive and prone to stress cracks at high temperatures. Carbon steel pipe, we felt, would have a problem handling the microbes and the concentration of iron sulfide found in the water, and the need for corrosion inhibitors would increase opex costs. Composite pipe, as well, would be too costly, as using it would require three lines of 8-inch diameter pipe. The pipeline would be about 15 miles long, so cost per linear foot was a significant consideration. The HDPE PE 4710 PE-RT pipe fit our needs to move up to 200,000 barrels a day of produced water.”

The Desert Hills Pipeline won the Project of the Year Award from the Plastics Pipe Institute, Inc. (PPI).

“By simplifying and streamlining the logistics of hot water transportation,” stated David M. Fink, president of PPI, “the PE-RT pipe system provided a solution to ongoing issues that oil and gathering facilities face. This includes state limitations and regulations on disposal, concerns around variable operating costs, and safety plus reliability. Because this project helped set the groundwork for an innovative solution that serves as an example and opportunity for others in the industry, it earned a Project of the Year Award for our Energy Piping Systems Division.”

The association’s annual awards program recognizes projects and members for exceptional contributions to the industry. Submissions in the association’s divisions are reviewed, evaluated and voted upon by the PPI members. PPI is the major North American trade association representing the plastics pipe industry.

The high temperatures of the water coming from miles down in the earth left the engineers with the choice of either cooling the produced water at higher cost or finding a corrosion-resistant pipe that could handle such temperatures.

The design team identified Performance Pipe’s PlatinumStripe 1800 Series Piping Products, manufactured using Dow INTREPID 2499 Polyethylene Raised Temperature (PE-RT & PE 4710), as a viable solution. The initial 11-mile trunkline for the new Desert Hills pipeline uses 18-in DR9 pipe that transitions to 20-in DR9. Cover was 4 feet, and the sections of pipe were heat-fused together, providing a leak-free joint.

The trunkline was completed and put into service during the first quarter of 2020.

According to Randy Knapp, engineering director of the Energy Piping Systems Division of PPI, “This is an excellent example of how PE-RT significantly expands the operation window for polyethylene pipe with its pressure ratings up to 180°F. PE-RT pipe can also be used in many types of harsh environments including mining, pulp and paper mills, oil and gas gathering plus nuclear facilities. It has the same inherent benefits as HDPE pipe including fusible, leak-free joints, it’s non-tubercular and will not corrode or decay.

“With fresh and recycled water streaming in at the rate of millions of gallons a day and leaving the area as highly brackish produced water or flowback, the integrity of the pipe and its joints is critical. Most leaks are from corrosion, gaskets and seals within a system. The PE-RT pipe with its monolithic structure basically eliminates the potential for leaks. This is extremely important, especially since there are about 50,000 permitted saltwater disposal wells just in Texas. High quality piping manufactured to rigorous standards serves the oil & gas industry and will continue to serve the energy industry with biogas, renewables and hydrogen.

“Feedback from the project was that it was a success and ‘win-win’ for Crestwood Equity Partners, disposal customers and surrounding landowners,” Knapp continued. “Using the PE-RT pipe for the project reduced capital and operating costs through the elimination of mobile chiller units and the lower cost of water gathering and disposal by pipeline instead of truck. Plus, there are satisfied landowners due to the reduced number of trucks, and because the buried, leak-free HDPE pipeline will help protect their fields.”

Ormond said that Crestwood will continue to grow its water processing business. “This was a great project for us, and we’re planning on adding several more wells to handle the produced water.”

Author: Steve Cooper has reported on oil, gas and infrastructure projects for several decades.

About PPI: The Plastics Pipe Institute, Inc. (PPI) is the major North American trade association representing the plastic pipe industry and is dedicated to promoting plastics as the materials of choice for pipe and conduit applications.

Comments