November 2021, Vol. 248, No. 11

Features

A Guide to New Robotics, Drone Technologies for Pipelines

By Nicholas Newman, Contributing Editor

There are an estimated 1.24 million miles (2 million km) of gas and oil pipelines worldwide. For example, Europe alone has 87,000 miles (140,000 km) of gas pipelines and another 24,850 miles (40,000 km) carry oil and related products.

Today, the pipeline industry can buy a wide range of technologies for automating, managing, monitoring, repairing and improving safety of pipeline infrastructure and operations.

Modern pipeline technologies include aerial and subsea drones, robots, sensor nets, artificial intelligence, software, cloud computing and machine learning alongside automation.

For example, the global Oil and Gas Pipeline and Transportation Automation Market, which includes North America, Asia Pacific, Europe, the Middle East, Africa and South America is forecast to increase by about $742.4 million between 2021 and 2025, according to Technavio 2021.

External Monitoring

Around the world, pipeline developers and operators including BP, Shell and Exxon are using orbital satellites and aerial and subsea drones to monitor the condition of their pipelines in real time.

Aerial surveillance is well suited to detect geo-hazards such as landslides, earthquakes or river erosion not only where they are expected in certain geographical areas along the path of a specific pipeline corridor, but also in unexpected places.

Mobile platforms such as aerial drones with a payload of thermal imaging technology and sensors can detect and monitor ground movements as small as a few millimeters per month – long before they can create enough force to compromise a nearby pipeline.

Although it takes a great deal of geological and technological knowledge to monitor such hazards with personnel on the ground, satellite and drone technologies can locate and identify such threats quickly and, thus, are crucial in ensuring safe pipeline operations.

Leading pipeline drone surveillance suppliers include UK-based Telespazio, Finish-based ICEYE and Dutch company Orbital Eye. Drone surveillance services are also available from Glasgow-based Balmore Inspection Services, Massachusetts-based SkyX and New York-based ULC Robotics. And, in line with the Paris Accords, mobile platform providers are adopting alternative fuels, including liquefied natural gas (LNG) and hydrogen fuel cells to power their drones, alongside various hybrid technologies to extend the time and distance traveled in the air.

Repair Robotics

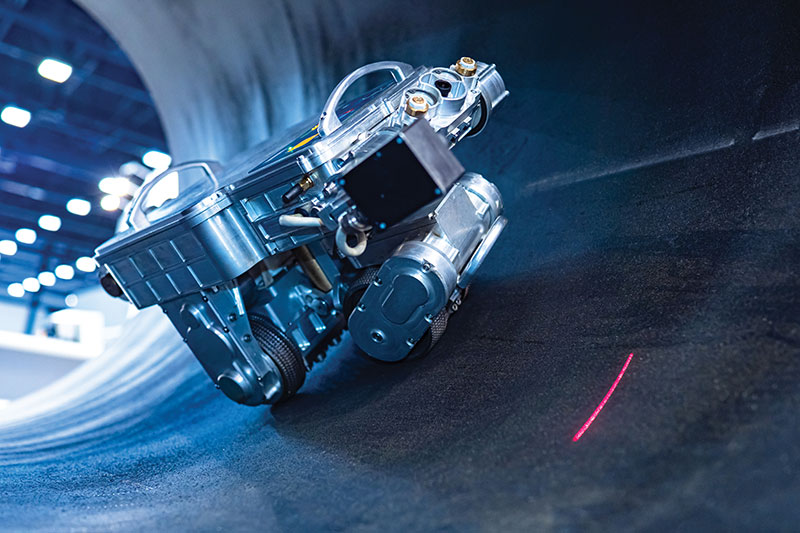

Traditionally, pipeline repairs were initiated by a technician who would locate and identify a damaged section, and a maintenance team would be sent out to make repairs. In the last decade or so, use of remotely controlled robots or pigs to patrol sections of pipeline carrying out internal inspections have become commonplace.

The first generation of pigs have been augmented by remote technician–controlled, sophisticated pipeline repair robots, equipped with a range of sensors cameras and tools to locate, identify and make repairs as and when required.

Often, such pigs can clean pipelines and patch and seal cracks in the pipe lining, thereby cutting potential leaks. This saves sending a crew to dig up the pipe. Using the most sophisticated pigs to routinely inspect and repair pipes saves time and money. In some situations, using the robot pig avoids the big expense and disruption of taking the pipeline out of commission to make repairs.

Overall, using robots is safer than requiring construction crews to dig trenches. It also keeps employees away from the hazardous material found in some pipelines. Companies providing pipeline pigging services include Tulsa-based T.D. Williamson, Liverpool-based SGS United Kingdom Ltd. and London-based Jee Ltd., among others.

HDS Technology

High-fidelity dynamic sensing (HDS) technology is set to become the new global standard in pipeline monitoring. HDS uses specialized fiber-optics (not to be confused with telecom fiber optics) fully distributed along the pipeline to sense every inch, 24/7 to detect both potential and actual leaks as small as a pinhole.

This technology is suitable for crude oil, bitumen, natural gas, refined products and wastewater pipelines. In practice, sensor data are collected and analyzed at self-contained transmission stations along a pipeline right-of-way.

“Event data” are transmitted securely to the operator’s control center, sometimes over wireless. Confirmed alarms – complete with exact location, audio file and pertinent strain and temperature measurements – arrive within seconds.

Such technologies can identify pipeline leak signatures (through a combination of acoustic, vibration and temperature variables); geotechnical events like landslides, earthquakes or floods (based on abnormal strain or vibration); and right-of-way security intrusions such as from nearby excavations, tampering activities and forest fires. Canada’s leading pipeline operator, Enbridge Pipeline, is a leading user of Hifi Engineering’s HDS technology.

Cloud Computing

An increasing number of oil and gas pipeline operators are making use of cloud-based computing as a means of crunching and analyzing huge volumes of data to improve managerial productivity and safety, cut costs and reduce risk.

For example, what would take months of traditional computation to develop and analyze a single “what-if” scenario, the power of cloud computing enables operators to study multiple sets of “what ifs” in just days. Data analysis by cloud computing is now quick, cheap and helps improve managerial decisions.

Also, it is now possible to use cloud-based processing and analytics to correlate dynamic, real-time data with static infrastructure data. A high-value, high-impact case is the mapping of seismic data during earthquakes to the locations of pipelines.

This is proving particularly valuable in Oklahoma, which has more than 43,500 miles (70,000 km) of state-regulated pipelines and a recent history of increasing seismic activity.

It is now possible for pipeline operators in Oklahoma to immediately evaluate the severity and depth of an earthquake in real time and, if necessary, inform supervisors who, in turn, can alert and inform pipeline integrity specialists of the location that needs prompt inspection and repair to prevent spills or ruptures.

Cloud computing could also reduce the effectiveness of ransomware attacks, such as the recent hack of the Colonial Pipeline, which had to shut temporarily. Providers of cloud-based services to pipeline operators include Seattle-based, Amazon subsidiary AWS Cloud Services, Microsoft subsidiary Azure Pipelines and London-based OMS.

Geospatial Solutions

Pipeline developers often use geospatial pipeline routing software to identify alternative pipeline routes for new or replacement of infrastructure. This technology is invaluable for assessing permitting requirements by analyzing jurisdictions, environmental and land ownership data.

In addition, details of crossing and impact reports to determine pipeline construction method, materials needed and land acquisition cost estimates can be downloaded.

This specialized software helps to identify and mitigate the environmental, political, archaeological and societal risks of reroutes and maintenance projects. The ability to assess permitting requirements for digs or pipe replacements within jurisdictions, land ownership and geological features, such as flood plains, at the touch of a button has revolutionized pipeline route planning, construction and maintenance.

Companies providing pipeline routing software include Terracon subsidiary, Missouri-based Pivvot, British Columbia-based Trimble TILOS Pipeline Management Software and Norwegian-based DNV. Customers include engineering consultancies such as Audubon, Pipeline Integrity Engineers Ltd. and Kimley-Horn.

Modern technology has reduced time spent in the field, facilitating desktop site assessments, integrated field data collection options and the ability to capture topical expert notes. These technologies will help countries upgrade, repair and rehabilitate or replace their aging pipelines.

As new pipeline projects become more complex, this new suite of technologies will prove invaluable for the efforts to reduce costs, increase productivity and meet tougher environmental regulations.

Comments