October 2021, Vol. 248, No. 10

Features

Isolation Enables Operator to Replace, Pressure Test Pipeline

Special to P&GJ

T.D. Williamson (TDW) completed its first SmartPlug isolation in offshore Nigeria, working for a major operator through its local partner, Strides Energy & Maritime.

Isolating the 165-mile (267-km) natural gas pipeline enabled the safe change-out and leak testing of platform valves without depressurizing the system.

This was the latest in a series of 47 SmartPlug operations TDW has provided for the operator since 2001. The companies have worked together all over the globe, including Bangladesh, Brunei, Malaysia, the Netherlands, Norway, the Philippines, the U.K. and the U.S.

“The first project in Nigeria, amid the pandemic, further extends our shared track record of success and adds to the extensive portfolio of services TDW offers across the African continent,” Vice President, Eastern Hemisphere Jeff Wilson said.

Double Block Isolation

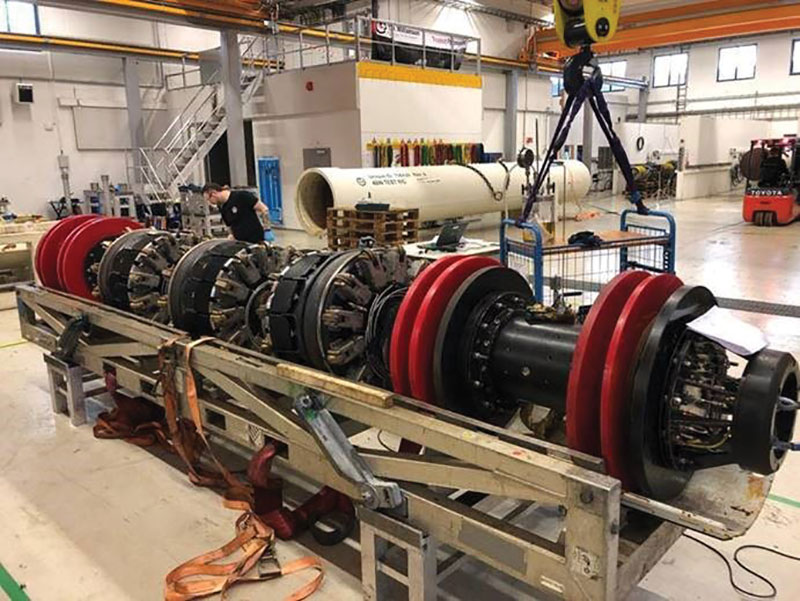

SmartPlug non-intrusive isolation technology is designed to minimize production downtime during critical repair and replacement work. For natural gas pipelines, it eliminates the need to flare product.

In its typical configuration, the SmartPlug system meets the criteria for a true double block isolation. In this case, two plug modules provided a double barrier to isolate pipeline contents at 80 bar (1,160 psi) line pressure; a third module allowed for in situ pressure testing of the new valves at 132 bar (1,915 psi) while the isolation remained undisturbed and in place.

The successful SmartPlug isolation remained in place for 32 days, completing the required work scope within the shutdown period.

Pandemic Challenges

Working with Strides and the operator, TDW overcame pandemic-related mobilization challenges to prepare for and perform the successful isolation within the operator’s urgent timetable.

Using videoconferencing capabilities enabled stakeholders in Nigeria, Norway, The Netherlands and the U.K. to virtually witness the factory acceptance testing (FAT). These efforts allowed TDW to deliver the equipment in just four weeks.

“This pandemic has forced us all to rethink the traditional ways we go about our business, from communication with our clients as well as within our own organization, and in the way we utilize remote technologies at our disposal,” TDW Project Manager Morgan Swanlund said.

Once the SmartPlug isolation tool was set, crews performed round-the-clock monitoring, both in person during the day and remotely (via satellite) by teams in Norway and Australia at night, when access to the platform was restricted. Wilson said this provided a foundation for future projects to leverage TDW remote monitoring technologies.

Comments