March 2023, Vol. 250, No. 3

Features

Flat Rail Cars Essential to Transport of Pipeline Segments

By Richard McDonough, P&GJ U.S. Correspondent

(P&GJ) — Flat cars and railroads offer midstream companies the flexibility to move the pipe that makes oil and gas transportation possible.

Trans Mountain Corporation certainly knows the significance of rail, having used flat cars to ship pipeline sections into position many times, including during its expansion project between Strathcona County, near Edmonton, in Alberta and Burnaby in British Columbia.

That project, essentially, involved the twinning of the existing 715-mile) 1,150-km) pipeline in western Canada, where the original pipeline was built in 1953.

Trans Mountain operates Canada’s only pipeline system transporting oil products to the West Coast, delivering 300,000 barrels of petroleum products each day Alberta and British Columbia, and a portion of Washington State.

For this particular expansion project, the company said it used more than 318,000 metric tons of new pipe, most of it 36 inches, with 42-inch and 30-inch pipe also required.

Three different lengths of pipe were used, determined by such factors as road design, accessibility and the ability to handle of the pipe in rough terrain or on steep slopes. Weather was also a factor, a Trans Mountain spokesperson said.

For example, the Lower Mainland of British Columbia, the intersections were not wide enough to accommodate larger lengths of pipe, and “the sharp turns in the mountainous areas also prevent trucks from carrying the longer pipe.”

Trans Mountain said the majority of the pipe for its Expansion Project was manufactured in Canada. Production of much of the pipe was at EVRAZ North America in Regina, Saskatchewan, and in Camrose, Alberta. According to the company, the pipeline material was sourced from EVRAZ’s recycled metal operations in Alberta, Saskatchewan, Manitoba and Ontario.

Beyond the pipe built in Canada, the pipeline company explained that the remainder of the pipe came from India and Japan, with the Japanese pipe being used specifically in areas known for seismic activity or ground movements.

Of course, pipeline sections are not alone among commodities in need of space of flat car, which can lead to logistical problems.

“Pipes are just one of many different commodities carried by flat cars,” said Jessica Kahanek, senior director of Media Relations for industry trade group Association of American Railroads (AAR). “As traffic in recent years has changed (for example, with the growth of rail intermodal service), it is safe to say that how this work horse of the rail car fleet has been used has changed as well.”

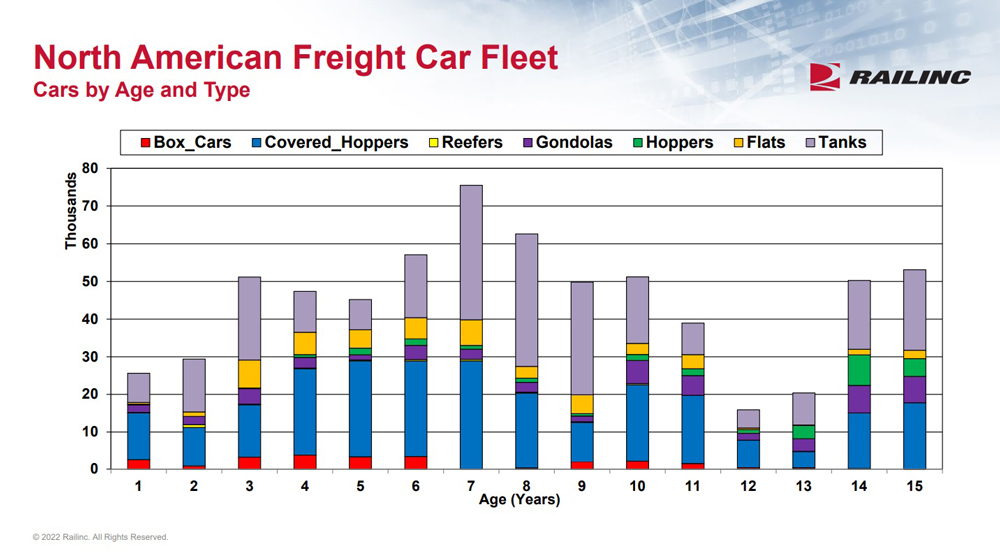

The growing use of rail can be seen in data from Railinc, which shows the number of flat rail cars in North America increased from 193,000 in 2010 to 206,000 in 2021.

Todd Tranausky, vice president of Rail and Intermodal at FTR Transportation Intelligence, a forecasting and consulting firm headquartered in Bloomington, Indiana, said during a recent webinar that the number of flat cars was expected to hold steady in 2024.

Unfortunately, he added, not all of the flat rail cars – whether they are new or already in the freight rail car inventories – work well for use in the pipeline industry.

“Certain flat rail cars are better suited than others for transport of pipe,” explained Tranausky. “About 35,000 to 36,000 of all of the available flat rail cars are appropriate to move pipe.”

Some flat rail cars, for example, are built to be able to carry steel beams and other heavier products.

Rail is also one of the key transport options used by TC Energy to move pipe. The company operates pipelines, storage facilities and power-generation plants in Canada, Mexico and the United States.

TC Energy uses a variety of transportation partners and suppliers to transport the materials needed to operate its systems.

“Flat rail cars are used to move line pipe, along with other transportation methods,” a company spokesperson said. “The line pipe for Coastal GasLink (CGL) was procured years ago and delivery was completed in early 2021.”

Currently, TC Energy suppliers are transporting line pipe by flat rail cars for the company’s NGTL expansion project. Both the CGL and NOVA Gas Transmission Ltd (NGTL) expansion orders being moved, at least in part, by flat rail cars.

Flat rail cars are used extensively by logistics companies like Dun Transportation & Stringing to move pipeline sections.

“We work hand-in-hand with the railroads and the steel manufacturers,” said Mike Nunnenkamp, executive vice president and COO of Dun Transportation & Stringing Inc. “We focus on operational logistics for the pipeline industry within the United States. We coordinate with the mill manufacturer, the contractor, and the oil and natural gas pipeline company.”

Recent Dun Transportation & Stringing projects involving rail were carried out for WhiteWater Midstream, a pipe project in Texas and Energy Transfer for pipe projects in Florida, Illinois and Ohio.

The company procured and prepared multiple pipe yards and rail sidings for the Enterprise Products – M2E3 Pipeline in Texas. Dun Transportation & Stringing also unloaded, hauled and stockpiled the pipe for this project.

Dun’s family business goes back to 1910, when it was known as Dunn Bros., and its involvement with the pipeline industry dates back almost as long, beginning in 1915.

“When things were slow, rail cars were put in storage,” Nunnenkamp said. “As the need for rail cars has increased, some of them that had been stored needed to be fixed up. Logistically, it can sometimes be challenging. We’ve been fortunate that we’ve been able to get access to all of the rail cars needed for our customers. Other folks have had more difficulties.”

In fact, many of the flat rail cars are owned by third-party rail supply companies.

“The third-party companies have existed for a while,” said Nunnenkamp. “Over the years, their market level grew to a higher percentage within the market.”

One of the companies that supplies and services flat rail cars to the pipe industry and other markets is AITX, which Sean Hankinson, chief commercial officer, said, offer key benefits in the hauling of pipeline sections.

“It [a flat car] is a durable railcar with a long, productive life cycle that works well with flat steel,” said Hankinson. “Another benefit is that it is effective as a storage option if needed by the shipper. It is a possibility to load the steel on to the flat car and store the materials in a storage yard as needed.”

While supply chain issues have affected the flat rail car inventory, according to several leaders within the industry, pipeline sections have still been able to be transported from factory to storage yards by rail.

“The population of flat cars in North America tends to skew older, and there are less new build cars than some other car-types; consequently, they are in short supply,” explained Hankinson. “However, given out fleet, one of the largest in North America, we’re able to meet the needs of our customers.”

Demand for brand-new flat rail cars appears to be greater than the supply, according to industry leaders. Other types of rail cars take precedence when it comes to manufacturing.

“There is a lot of demand for many new-build railcars of all types, and many manufacturers are queuing-up tank cars and covered hoppers as priority to flat cars based on the installed base for those types,” said Hankinson. “This is where AITX shines, having the breadth and scope to find these assets for our customers.

“This is a sought-after car-type as there is a high demand,” said Hankinson.

He indicated that shippers looking into using this type of car should work with a diversified lessor that has access to these cars or has the type of relationships to find the railcar that a shipper needs.

According to a report by AAR, the aggregate capacity of flat rail cars in North America in 2021was about 22.4 million tons. In 2012, the aggregate capacity was 20.5 million tons. Aggregate capacity of flat rail cars increased to 21 million tons in 2016 and then to 21.8 million tons in 2019.

Author: Richard McDonough writes about energy infrastructure-related issues in the United States, including the column “The Nuacht Of Pipelines.” He can be reached at newsaboutamerica@gmx.us.

Comments