July 2023, Vol. 250, No. 7

Features

Developments in Custody Transfer Metering of Natural Gas

By Alex Frei, Senior Project Manager, Stantec

(P&GJ) — Natural gas has become an even more important energy source as the world looks to transition away from coal-fired power plants. Natural gas emits about half of the carbon emissions as coal, so it has many countries looking to adopt it as a larger part of their energy infrastructure.

This has been especially apparent over this past year, as we’ve seen global challenges in natural gas supply chains due to events like the war in Ukraine.

Luckily, Canada has significant natural gas reserves and is starting to be play a bigger role in the world LNG market. Tourmaline has started shipping LNG through Cheniere in Texas, LNG Canada is nearing completion of its export terminal in Kitimat, British Columbia, and initial site work has started on Woodfibre’s proposed site in Squamish, British Columbia.

These developments – plus domestic consumption and exports to the United States – are provided by Canada’s extensive and well-developed natural gas production and pipeline transportation systems. By the end of 2022, Canada was producing an all-time high of almost 18 Bcf/d. With LNG Canada coming online in 2025, production will exceed 20 Bcf/d.

All this gas needs to be measured throughout Canada’s pipeline systems and into distribution systems and LNG plants. While large parts of Canada’s natural gas pipeline systems have been in service since the 1950s, growth in production requires new facilities to be built, including the Coastal GasLink system which will supply LNG Canada’s plant.

Pipeline operators are interested in improving their designs and taking advantage of technological developments to improve performance, reduce costs, and provide increasing returns to their shareholders. One component of that process is knowing how much gas is sold, also known as custody transfer metering.

What Is Custody Transfer?

Custody transfer refers to the ownership exchange of natural gas from one owner to another. Custody transfer measurement is required at the point where the ownership of the gas changes hands. Most people are familiar with the gas meter on the side of their house or the gasoline pump they use to fill their cars.

These are custody transfer measurement points. These custody transfer measurement devices are government certified so that the level of accuracy is consistently maintained, and customers know they are getting the amount of gas or liquid for which they pay.

In industrial custody transfer between producers, pipelines, and distributors, the American Gas Association (AGA) measurement standards are universally used in North America. Governments and industry accept these as custody transfer standards where the product is not being sold to the end user.

For many years, large volume natural gas custody transfer measurement has been accomplished with a Daniel Senior Orifice meter, which adheres to AGA 3 measurement requirements. This measurement technique produces excellent results.

Ultrasonic Flow Measurement (UFM)

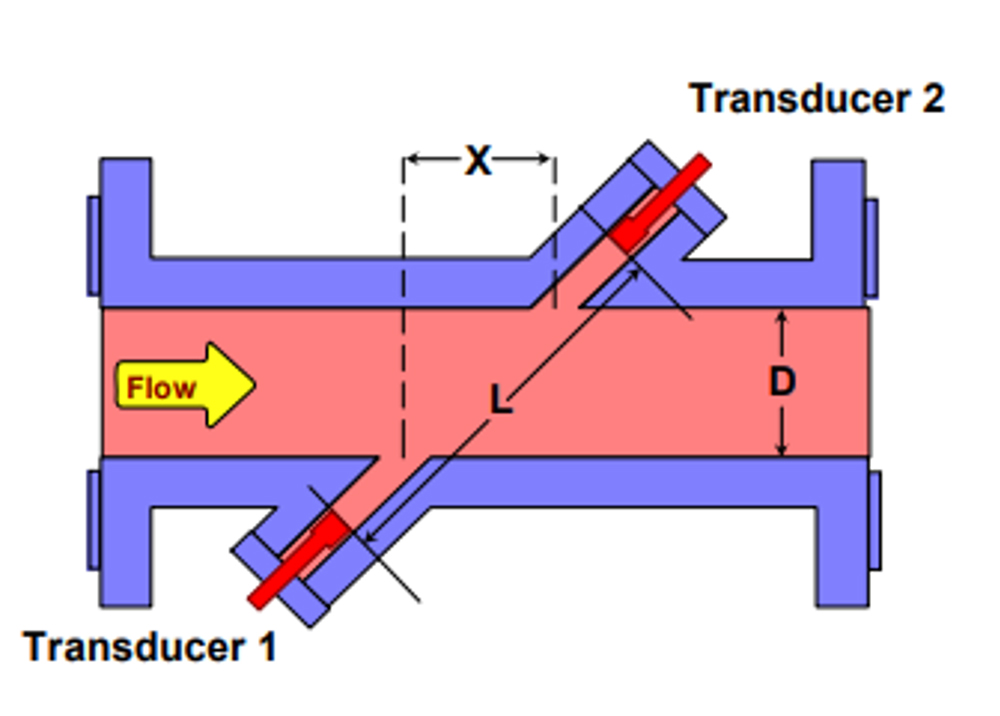

An alternate fluid measurement technology has existed for decades: Ultrasonic measurement. The basic concept is shown below1:

A signal is sent from transducer 1 (T1) to transducer 2 (T2) and the time is measured. The process is then reversed, and the time measured again. The difference in time is related to the velocity of the liquid flow. This technique can be applied to both liquids and gases. Although, with a lower density, gas has been more of a challenge to measure accurately.

Measurement Device

The diagram above is a single-path ultrasonic meter. Various methods for flow profile compensation have been developed over the years, essentially by adding the number of ultrasonic paths across the gas stream. In addition, flow straighteners have been used to create a more ideal flow profile in the meter.

Over the past three decades, the design and placement of the transducer pairs has been improved to a British Gas 4-Path standard, which had been adopted by a number of flow meter manufacturers2. Recently, this patented British Gas layout has been improved to an 8-path layout for swirl immunity and ultra-high accuracy measurement3.

Number of Paths

Let’s explore some of the differences between a 4-path UFM and an 8-path UFM.

4-Path UFM4

- 4-path chordal design reduces susceptibility to meter fouling

- Cross-flow compensation with 3-Axis measurement paths

- Meter Link advanced diagnostics package 8-Path UFM5

- 8-path chordal meter paths allows the meter to cancel out asymmetrical velocity effects

- Provides higher resolution of the flow and can more accurately calculate swirl, compensating for non-ideal flow distortions that result from pipe bends, shorter straight runs, or smaller design

- Requires only five upstream diameters of straight run and no flow conditioner

- Transducers are extractable under pressure; easily retractable without depressurizing the line and does not require a high-pressure extraction tool.

Diagnostics, Software

As with a lot of recent technology, there have been significant improvements to the operation and maintenance of UFMs. In the case of the Rosemount 8-path meter, the need for data analysis and troubleshooting has been significantly reduced and the user can obtain a clear measurement verification result. Some specific features include:6

- Clear measurement verification results

- Transducer health monitoring

- Bore buildup alarm

- Blockage alarm

- Abnormal profile alarm

- Liquid detection alarm

- Reverse flow alarm

Transition to UFM

Companies are interested in UFM as a method to maintain measurement certainty, reduce the size and weight of meters, reduce energy loss, and if possible, reduce the footprint of the meter runs. Orifice (differential pressure) metering has been the standard gas measurement for decades. As noted above, AGA 3 defines the industry-accepted custody transfer orifice meter run requirements.

In large flow volume applications, the orifice meters can get large and heavy. They also typically require 15 upstream and downstream straight run diameters or more, depending on the upstream piping configuration.

This results in the meter run being quite long in bigger applications. For example, for a 12-inch meter, the upstream straight run would be 15 feet, and the downstream run the same. Adding 19 inches for the meter, the length of the meter run would be over 31 feet7.

UFM has been used for years offshore where space and size is a premium. UFMs have a greater overall throughput capacity compared to the same size orifice meters.

Some of our clients have used 4-path UFMs for a few years now, gaining these advantages. More recently, 8-path UFMs have been utilized for their ability to require fewer upstream and downstream diameters, further reducing the meter and meter station footprint. AGA 9 is the measurement standard used for UFM and can include AGA 10 speed of sound calculations.

Field Application

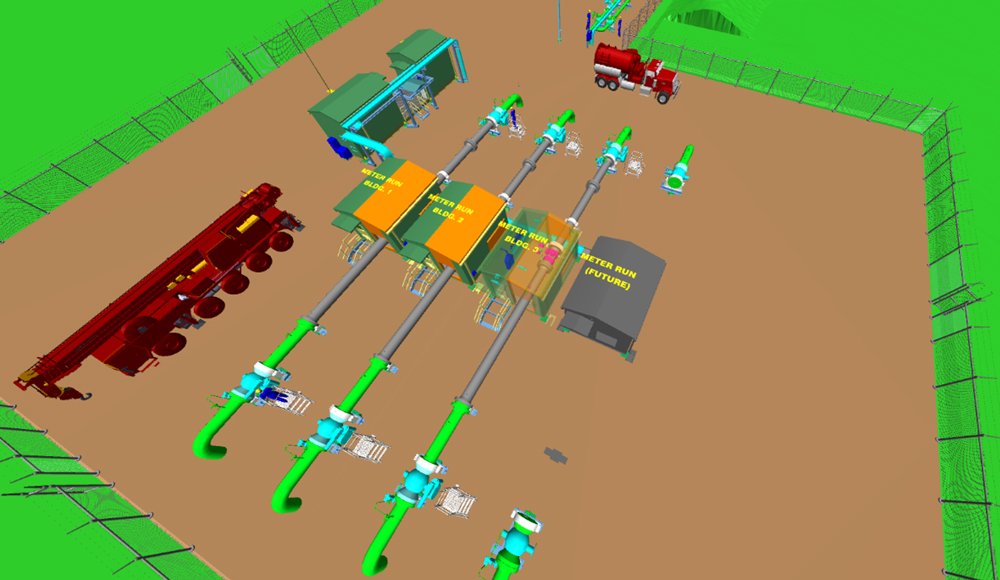

Designs of meter stations incorporating UFM are more compact than those using orifice meters, allowing for a smaller footprint. As with orifice meters, a meter station design may incorporate meter redundancy to accommodate an outage of a meter run for periods of maintenance.

A typical configuration would be the so-called N+1 setup, where three-meter runs are built and two can handle the full required flow capacity. The +1 is a spare meter for maintenance purposes, allowing the meter station to get the maintenance work it needs without reducing throughput.

An example of a three-meter run to the meter station for a 2 Bcf/d meter station using three, 20-inch UFMs is provided in a 3-D model:

Increased Metering

Advancements in the technology, software and diagnostics have allowed the use of multipath UFMs for custody transfer. The benefits are a smaller footprint of a meter station, easier maintenance, reduced fowling, and improved diagnostics to troubleshoot problems. The current generation of UFMs provide benefits of reduced weight and maintenance, while retaining custody transfer level accuracy and repeatability.

As Canadian gas production continues to increase, technical advancements in custody transfer metering are helping reduce facility costs while maintaining metering excellence. This is especially needed as we work to increase domestic production and reduce the need for coal-powered generation around the world.

We won’t be able to build a 100% renewable energy future over night, but we can reduce emissions right now by replacing the need for coal with natural gas.

Comments