June 2023, Vol. 250, No. 6

Tech Notes

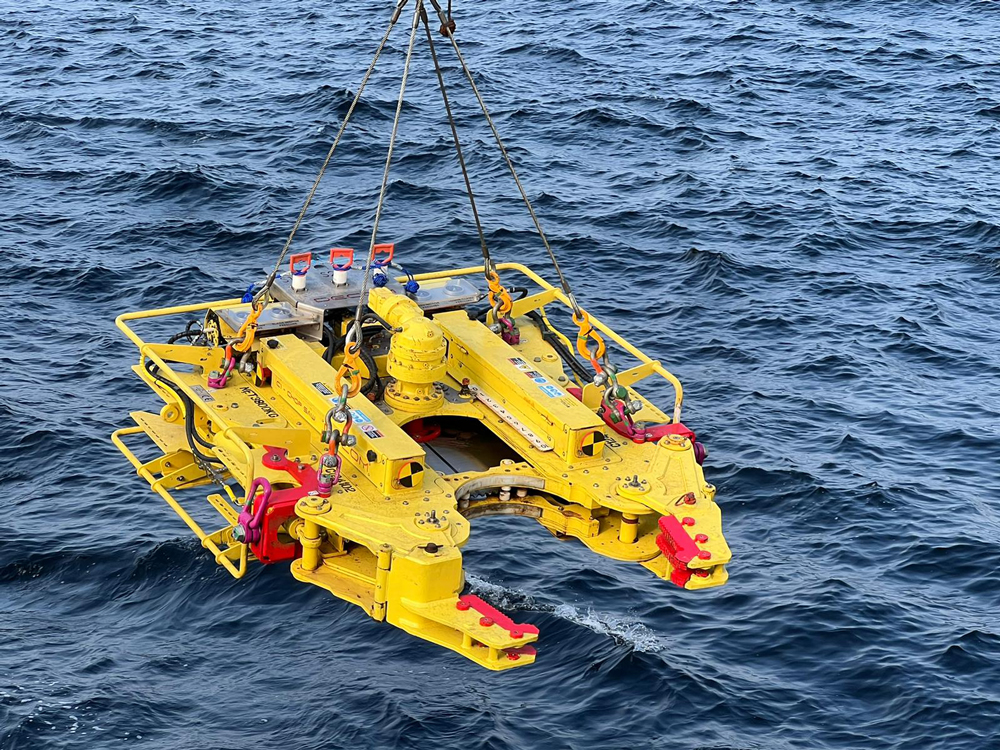

Making the Cut in Decommissioning Project

Special to Pipeline & Gas Journal

(P&GJ) — Decom Engineering’s specialized cutting technology has been successfully deployed on a decommissioning project off the coast of West Africa.

A C1-24 chop saw was used in water depths of up to 3,445 feet (1,050 meters), as part of an operation to recover a jumper connector on behalf of Total Energies in the Gulf of Guinea, the coast of the Democratic Republic of Congo.

The workscope included cutting of the insulated 6-inch Duplex flowline at each end of the jumper, with the chop saw deployed by ROV with hot stab capability and using a Tungsten carbon tip blade with an average cutting time of an hour, 15 minutes.

The Congo project follows other successful deployments on behalf of major oil and gas operators and contractors, including at locations in the North Sea, Mauritania, Norway and Gulf of Thailand.

Established in the United Kingdom in 2011, with bases in Aberdeen and Belfast, Decom is an R&D specialist, focusing on the design and fabrication of cutting solutions and innovative decommissioning equipment, with a growing reputation for providing complex deep water project solutions.

“Decommissioning redundant piping infrastructure or repurposing assets to be converted for low- or zero-carbon energy storage is a massive global market, and we are committed to investing in research and development,” said Engineering Managing Director Sean Conway.

The C-1 chop saw range is certified for use in water depths of up to 6,560 feet (2,000 meters). The company is expanding its C1 chop saw range with a new model that will be capable of cutting piping infrastructure of up to 46 inches.

Comments