Stopping Methane at the Source: Compressor Station Solutions

By S.L. Chakravorty, Independent Consultant, Oil and Gas, India

(P&GJ) — Gas compressor is the heart of the transporting natural gas (NG) to long distances through cross country pipelines and the centrifugal compressors are the preferred choice in its transportation.

In petroleum refining operations also, especially for secondary processing units, recycle gas compressors are used to circulate hydrogen-rich gas through catalysts or conversion reactors to make finished products.

Compressor stations for transporting NG can be the source of considerable greenhouse emission (methane emission) if not controlled. Oil and gas companies along the supply chain are under pressure to reduce Greenhouse gas emission. This article deliberates various source(s) of such emission and the options available to control and minimize them.

Process Hazard Analysis

Process hazard analyses (PHAs) for compressor operation, especially for start-up and shutdown activities are needed to answer the basic process safety questions: What can go wrong? What safeguards are needed? Are safeguards provided are working?

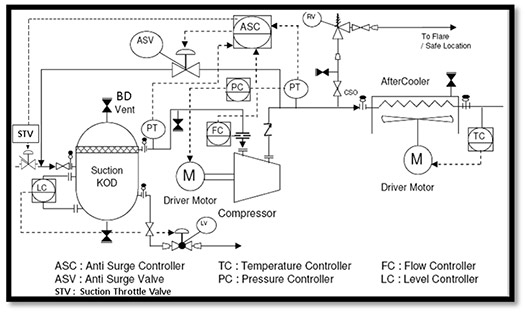

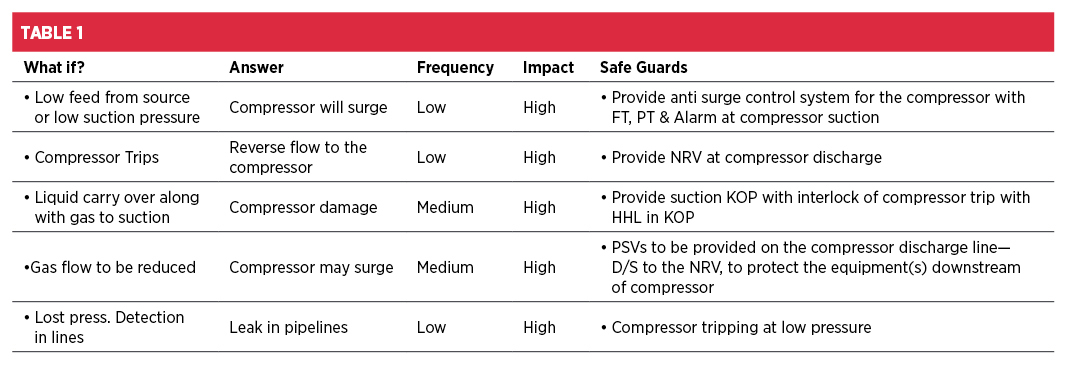

To answer the questions, the example using “what if” methodology for fixed speed centrifugal compressor (motor or gas turbine driven) is considered, for example. The process flow diagram indicating compressor’s typical control system including the anti-surge control as required (Figure 1).

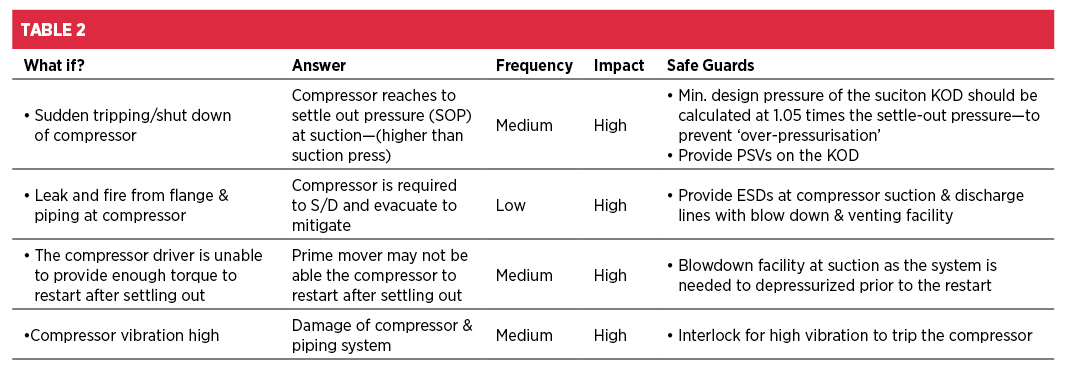

When conducting “what if” analysis, it is essential to address the most important process safety information, such as the settle out pressure (SOP) of the gas compressor and its importance in ensuring operating integrity.

Settle Out Pressure

In case of an unplanned event, such as emergency shutdown or power failure, the compressor trips first followed by the anti-surge valve opening (Figure 1). This causes the gas content in the suction side and discharge side mixes each other and are equalized out.

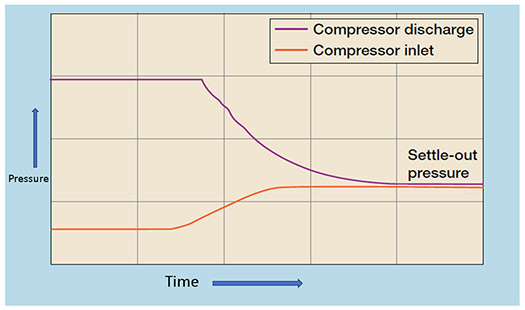

This equilibrium pressure throughout the compressor loop is called settle out pressure (SOP). Figure 2 shows typical time vs compressor discharge, inlet and settle out pressure while the suction pressure at settled out condition reaches higher than normal suction pressure of the machine.

The main reason for knowing the SOP is to define the design pressure of equipment, piping and instruments located on the suction side of a compressor loop, to avoid unnecessary flaring during compressor start-up or shutdown.

SOP is also necessary to establish the minimum dry gas sealing pressure in case of compressor pressurized shutdown.

Under the pressurized shutdown since the isolatable section is kept pressurized, the compressor gets locked as the gas grips on tightly onto the rotor and impellers, preventing rotation and the much higher torque would be needed to restart the compressor.

Settle-out pressure is used not only to set design parameters for piping and equipment on the suction side of the compressor, but it also plays an important part in start-up because higher settle-out pressures correspond to higher torque requirements.

If a compressor driver is unable to provide enough torque to restart after settling out, for instance, the system would need to be depressurized prior to the restart.

Also, as per API 521, the minimum design pressure of the separator drum/ scrubber should be calculated as 1.05 times the settle-out pressure. It provides an adequate differential between the operating pressure and set pressure of the pressure relief device for a compressor shutdown contingency.

The “what if” analysis for the compressor shown in the Table 1 and Table 2.

Legend:

L : Frequency, S: Impact

Compressor Stations

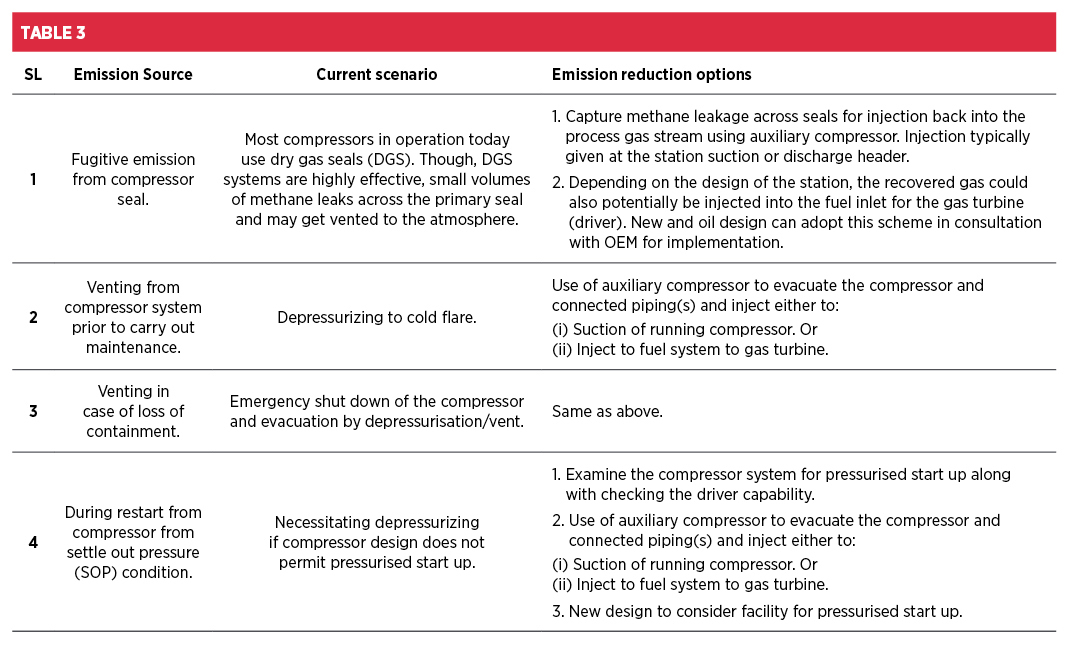

Oil and gas companies along the supply chain are under pressure to reduce greenhouse gas emissions. Compressor stations for transportation of NG that use fixed speed electrical motor/turbine to drive the compressor can be a significant source of methane emissions from the following sources, if not controlled.

- Fugitive emissions from compressor seal.

- VOC emission due to venting from compressor system to prior to carry out maintenance.

- An emergency shutdown of the compressor and evacuation through depressurization, in cases of loss of containment.

- Necessitating depressurizing during restart as compressor goes to settle out pressure (SOP).

Environmental Hazards

The environmental hazards from compressor operation specially from above aspects, needs to be analyzed, to derive safeguards from such hazards, while conducting the PHA.

Possible options to minimize methane emissions:

Table 3 listed the options to be securitized, depending on the design of the gas compression system and configuration.

Green Hydrogen

Hydrogen is now at the heart of net zero and compression systems will be needed, as with NG, to transport green hydrogen from generation centers to the end users.

Green hydrogen produced using renewable energy is considered precious, no one can afford to lose it from compressor station in the form of fugitive emission or venting. It would be prudent to implement the emission prevention options from compressor stations in its design stage itself.

Conclusion

Compressor stations can be the source of considerable greenhouse emission (methane emission) if that is not prevented.

Use of auxiliary compressors to evacuate the holdup material prior to conducting maintenance and recovery through injection would go a long way to control and prevent such emissions.

Author: S.L. Chakravorty is the former executive director of Indian Oil Corporation Ltd, India. He has also worked in the Oil Industry Safety Directorate (OISD), a body formulating safety standard for oil and gas in India. Currently he works as an independent consultant based at Noida, in the Uttar Pradesh state of India. His specialities are process safety and safety auditing. He can be reached at slchakravorty.iocl@gmail.com