De-Stressing Pipe Stress Analysis for Integrity Management Programs

Author: PHIL SENIOR, Bentley, Exton, Pennsylvania

(P&GJ) — Piping serves as a crucial element in our modern society, encompassing transmission pipelines, processing facilities and power generation plants. It must safely transport and contain its contents regardless of temperature, pressure, corrosivity and all external loads, including wind, snow, seismic activity and dynamic events. It must also meet the proper codes, which vary by country, as well as by sector.

Piping layouts and support systems can be extensive and complex, with a long list of potential applied loads. The techniques and approaches used for adding these forces are critical to accurately evaluating the resulting stresses and confirming that the piping design is safe for both humans and the environment. The problem is further complicated by a profusion of national and international codes that may be applicable to a particular industry or application.

Fortunately, the task can be dramatically simplified with the right pipe stress analysis software. This article discusses pipe stress analysis in general and describes the key software features that are required to perform an accurate, optimized and code-compliant stress analysis for a given piping application.

Pipe design vs. analysis

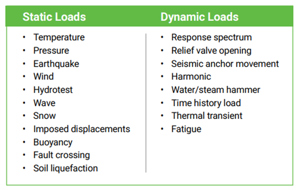

Before delving too deeply into the topic, it is worth clarifying that there are generally two steps to piping system engineering: design and analysis. The first step, design, creates the overall piping network. In this phase, the pipe sizes are calculated based on pressure drop and flow requirements. Meanwhile, material selection and pipe pressure classes are chosen based on process media, pressure, temperature, process conditions and other factors. Typically, in this phase, a full-scale 3D computer-aided design (CAD) model is generated that includes all the details required for construction. Once this piping network has been designed, it must then be thoroughly analyzed to ensure it can handle the various loads placed upon it over its lifecycle. These stress loads are much more extensive and varied than one might initially imagine, and they can include both static and dynamic loads (FIG. 1).

Stress analysis seeks to quantify and document these loads, then apply them individually and in combination to confirm the pipe design is adequate and capable. The requirements of this design analysis can vary significantly by country and application. As a result, there may be multiple standards that must be applied to validate the piping design and confirm its suitability.

A key challenge is the iterative nature of this design process. A piping system is first designed and then thoroughly analyzed. Any issues identified in the analysis usually result in piping design changes, with the resulting new design re-analyzed to confirm the issues have been addressed. As a project progresses, further adjustments due to structures, supports, piping, tanks, pumps and other elements are inevitable, and each of these will require yet another round of design and analysis to confirm suitability. Therefore, the ability to transmit data between the piping design and stress analysis software is essential for this effort.

Data model transfers

A defining requirement for any pipe stress analysis software is the ability to accept models from design software, perform analysis and create easily interpreted graphic results that can be documented in Microsoft Word or Excel. The software must also be capable of importing stress modeling and test data, as well as exporting analysis results in various formats. Higher-tier pipe stress analysis software can seamlessly transfer information between many platforms and formats.

Incorporation of mechanical standards and codes

Another major requirement for any piping stress software is the incorporation of applicable national and international codes. A capable software package will support both the latest and past revisions of major global piping codes, such as:

- ASME B31.1, B31.3, B31.4 and B31.8

- ASME Section III (Nuclear Class), NB, NC and ND

- ASME B31.12 [Hydrogen Piping and Pipelines (IP/PL)]

- ASME NM (non-metallic)

- ASME B31.4 Ch IX, B31.8 Ch VIII, DNVGL-ST-F101, CSA-Z622 offshore

- ASME B31.J SIFs (stress intensification factors) and flexibilities

- Canadian National Standard (CAN/CSA)-Z662

- European Standards (EN)13480 metallic and EN14692 non-metallic.

Providing the latest code editions is an important feature of any software stress analysis package, so the chosen software should have this capability and support it with built-in American Society of Mechanical Engineers (ASME) B31J flexibility and stress intensification factor calculations. The ability to work with both current and legacy editions of codes allows the design to meet the specific needs of the project, while benefitting from the latest and newest features of the program.

Running the stress analysis

Once the data has been imported and the appropriate standards have been enabled, it is time to perform the analysis, which often involves an overwhelming array of calculations. Both static and dynamic loads must be considered, and those loads must often be applied individually, collectively, and, at times, sequentially to correctly model the system. The list in FIG. 1 shows just how varied the design loads can be.

The right software package will incorporate a host of design features to simplify user interaction and allow results to be easily interpreted (FIG. 2). More capable stress analysis packages will include extensive libraries of American National Standards Institute (ANSI)/ASME, Deutsches Institut für Normung (DIN), EN, Japanese Industrial Standards (JIS), general dimensions (GD), Chinese National Standards (GB), Russian/Commonwealth of Independent States (CIS) national standards (GOST) and glass/fiber reinforced plastic (GRP/FRP) standard piping components and materials, and they will also include single-line, wireframe and solid-render drawing modes. The software should also include connectivity checks to avoid model disconnects, and it should incorporate structural steel and expansion joint models from multiple countries.

In addition, ancillary stress calculations should be performed around rotating equipment, flanges and vessel connections to completely evaluate the resulting stress and loads. Higher-end packages incorporate these features into the software or offer options to handle these conditions.

The software should also be capable of defining and applying multiple analysis sets to the piping network, which might include linear and nonlinear scenarios (with sequencing), hot vs. cold modulus, pressure vs. no-pressure stiffening and a wide range of soil properties.

Design optimization

One of the typical requirements of stress analysis is locating and designing proper pipe supports. While a seasoned engineer can find a solution that is acceptable, a more capable software solution can run hundreds of iterations and quickly find an optimal support solution that meets the necessary design criteria at minimal cost (FIG. 3). These optimization features can save significant money in materials and construction costs, often paying for themselves in a very short time.

The cost of incorrect pipe stress analysis

The list of failed projects due to inaccurate pipe stress analysis is legion. Two examples are discussed here.

A solar power plant project was designed and installed in the field. Before the piping was connected to the turbine nozzle, the springs were released, and the piping dropped 150 millimeters (mm) instead of the anticipated 2 mm (FIG. 4). Upon further and more careful analysis, it was determined that the dead loads had been grossly underestimated by more than 40%.

Project startup was delayed several weeks to assess and resolve the design flaws, and the installation required significant capital cost to rework and resolve the issue. The design company also paid contractual penalties due to lost production.

A 40-megawatt heavy fuel power plant startup was interrupted when an expansion joint failed, damaging the engine, valve and structure. Thirty days later, a second startup was interrupted due to significant vibration, necessitating an additional 15-day shutdown. Detailed modal analysis of the piping and structure combination revealed a resonance problem that had been missed in the initial analysis (FIG. 5).

The more thorough follow-up stress analysis discovered a missed expansion joint thrust load, corrected the modeling of trunnion supports, and considered the flexibility of the structure, which had been ignored.

On the more positive side, there are a multitude of projects which have utilized the right pipe stress analysis software combined with well-integrated pipe design, vessel design and rotating equipment design software to create a fully integrated software model of the facility and equipment. Many of these projects have been able to reduce schedules by months, since these packages have enabled multidiscipline collaboration, while allowing design changes to be quickly and automatically revalidated as the models were modified.

Takeaway

Pipe stress analysis is complicated, but it does not have to be stressful when the user applies the right software. If faced with the task of choosing the best option for a large piping design project, users are encouraged to carefully evaluate the alternatives, confirm the software capabilities and choose wisely. The time and effort expended in the software evaluation and selection process will be well spent due to improved project designs and accelerated schedules.

NOTE

a Bentley’s AutoPIPE

About the author

PHIL SENIOR is the Director of Product Management at Bentley, where he is responsible for product management and the quality of analysis products. He previously worked as a pipe stress analyst before moving to product management, and he is currently responsible for crafting a product vision that aligns with Bentley’s strategy. Senior also ensures that this vision translates into meaningful value for end users by identifying pain points and understanding workflows to articulate requirements to internal software developers. He has worked primarily in the nuclear, processing and power generation industries, and he is a Chartered Mechanical Engineer and Fellow of the IMechE. Senior earned a BS in mechanical engineering from Nottingham Trent University.