January 2022, Vol. 249, No. 1

Tech Notes

University of Houston’s Falcon In-Pipeline Leak Solution

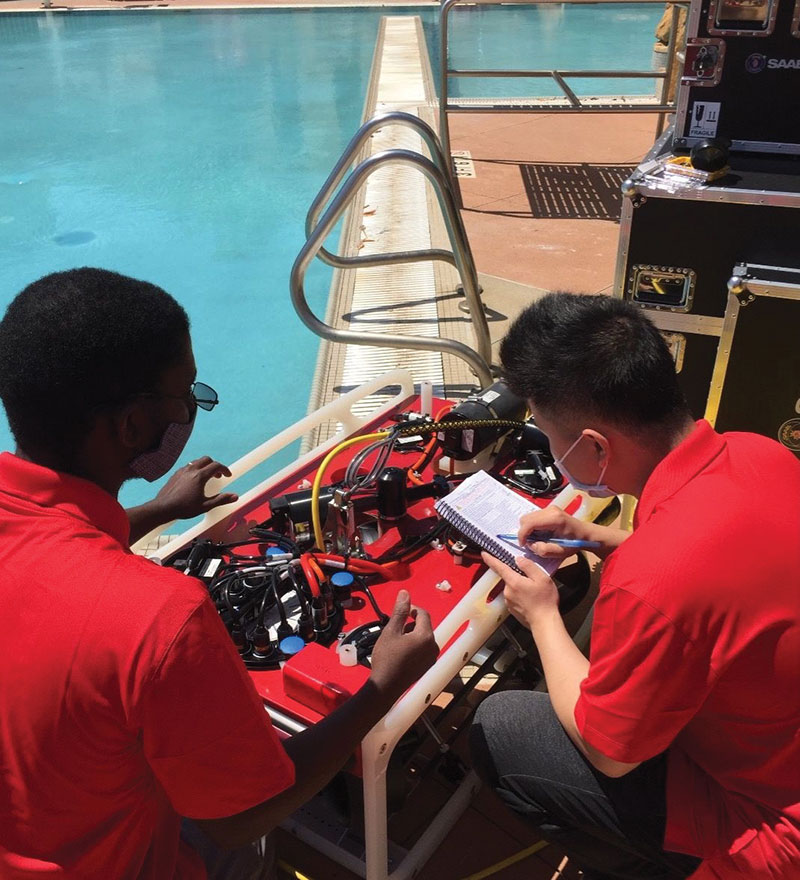

A breakthrough in leak risk detection at oil pipe flanges comes from research by the University of Houston using a Saab Seaeye Falcon robot as a development platform.

Called SmartTouch, the solution involves integrating robotic manipulator controls into the Falcon that provide multiple stress wave sensors for touch-based inspection of bolted joints, along with the latest structural health monitoring and inspection technologies. Video cameras and scanning sonars are also integrated into the system.

Finding a time- and cost-effective robotic solution to identify flanges at risk was the university’s key objective because bolted flanges can loosen when ocean dynamics shift pipelines. The difficulty of locating flanges at risk makes their timely inspection key to the prevention of oil spills.

The research team led by Dr. Zheng Chen, assistant professor in mechanical engineering and director of bio-inspired robotics, together with Dr. Gangbing Song, professor in mechanical engineering, includes six Ph.D. students.

Totally Automated

For the university, the ease of systems integration comes from the intelligent distributed control architecture. The module-focused iCON endows each device with its own microprocessor for individual control and offers a future-flexible concept that can readily adopt evolving technologies.

The robotic system, Chen said, “can totally automate and dramatically reduce the cost and risk of subsea inspection, leading to safer operations of offshore oil and gas pipelines.”

Recording over a million hours of undersea operations, the Seaeye Falcon is depth-rated to 3,280 feet (1,000 meters) and can hold steady in strong cross-currents while packed with cameras, sensors and tools.

Comments